In the competitive world of business, companies constantly seek ways to improve efficiency, reduce costs, and deliver high-quality products or services. One of the most powerful tools to achieve these goals is the Lean methodology. This blog will delve into what Lean methodology is, its key principles, and how it can be applied to quality management. We’ll also outline the process and provide real-world examples to illustrate its effectiveness.

What is Lean Methodology?

Lean methodology is a systematic approach designed to eliminate waste within a manufacturing or service process, thereby enhancing value for the customer. Developed as part of the Toyota Production System, Lean aims to optimize workflows by focusing on efficiency, minimizing resources, and ensuring the highest quality of output.

Core Principles of Lean Methodology

Lean methodology is guided by five foundational principles:

Value: Identify the value from the customer's perspective and focus on delivering it.

Value Stream: Map the entire process to uncover and eliminate waste.

Flow: Ensure a smooth flow of processes without interruptions.

Pull: Implement a demand-driven production system to create products only as needed.

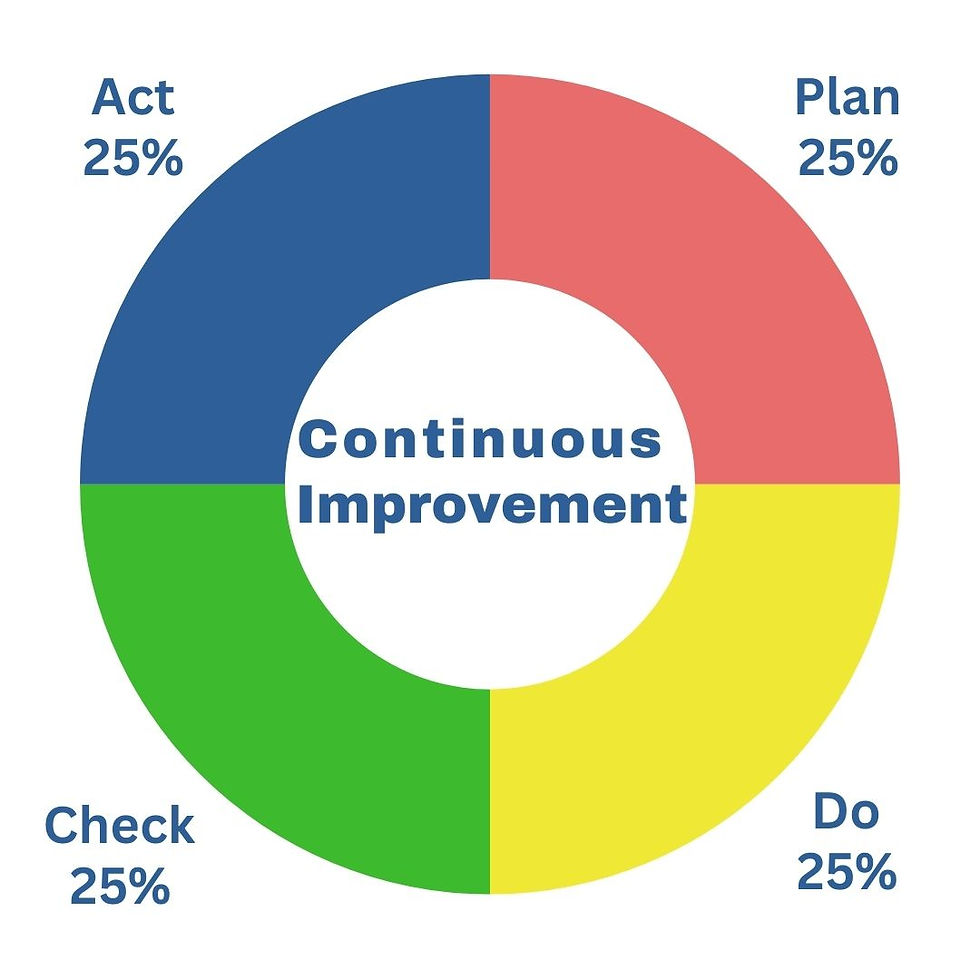

Perfection: Commit to continuous improvement and strive for excellence in all processes.

The Lean Methodology Process

Applying Lean methodology to quality management involves a clear and structured process. Here’s how you can implement it:

Define Value

Start by understanding what your customer values the most. This could be product quality, speed of delivery, or cost-effectiveness. Your goal is to focus on activities that add value from the customer’s viewpoint.

Map the Value Stream

Create a visual map of the entire process, from raw material to finished product. This mapping helps in identifying every step involved and highlighting areas where waste occurs—whether in time, resources, or labor.

Establish Flow

Once waste is identified, work on streamlining processes to ensure a smooth, uninterrupted workflow. This may involve reorganizing workstations, reducing bottlenecks, or improving communication between departments.

Implement a Pull System

Adopt a pull-based production system where items are produced based on actual customer demand rather than forecasts. This minimizes overproduction and excess inventory, leading to a more efficient process.

Pursue Perfection

Lean is not a one-time effort but a continuous journey. Regularly review your processes, seek feedback, and make incremental improvements to achieve and maintain the highest quality standards.

Lean Methodology in Quality Management

In quality management, Lean methodology is used to focus on reducing variability and preventing defects in the production process. This is achieved by standardizing processes, enhancing employee skills, and continuously monitoring performance to detect and correct any issues before they affect the final product.

Example: Consider a company that manufactures automotive parts. By using Lean methodology, the company maps its production process and identifies a high defect rate during the assembly stage. To address this, they standardize the assembly procedures, provide targeted training for workers, and introduce quality checkpoints. As a result, the defect rate drops, production speeds up, and overall customer satisfaction improves.

Benefits of Lean Methodology in Quality

Increased Efficiency: Streamlining processes and eliminating waste leads to faster and more efficient production.

Higher Quality: Continuous monitoring and improvement ensure that products meet or exceed quality standards.

Cost Savings: Reduced waste, lower defect rates, and optimized use of resources contribute to significant cost savings.

Faster Time-to-Market: Lean processes enable quicker response times and faster delivery of products to the market.

Employee Empowerment: Lean fosters a culture of continuous improvement where employees are encouraged to identify and solve problems.

In Lean methodology, waste is anything that does not add value to the customer. Lean identifies seven common types of waste, known as TIMWOOD:

Transportation: Unnecessary movement of materials or products.

Inventory: Excess products or materials not being processed.

Motion: Unnecessary movement by people.

Waiting: Idle time waiting for the next step in the process.

Overproduction: Producing more than is needed.

Over-processing: More work or higher quality than required by the customer.

Defects: Efforts caused by rework, scrap, or incorrect information.

Real-World Example: Lean at Toyota

The Toyota Production System (TPS) is a prime example of Lean methodology in action. Toyota revolutionized the automotive industry by applying Lean principles to its manufacturing process. By focusing on waste elimination, optimizing workflow, and empowering employees to contribute to continuous improvement, Toyota consistently delivers high-quality vehicles with minimal defects, setting a standard in the industry.

Lean methodology is a versatile and powerful approach to quality management that can benefit businesses across various industries. By focusing on customer value, eliminating waste, and continuously improving processes, companies can enhance product quality, reduce costs, and improve overall efficiency. Whether you are in manufacturing, healthcare, or any other sector, implementing Lean principles can help you achieve your quality management objectives and maintain a competitive edge in the market.

Understanding NVA, VA, and ENVA Processes in Lean Methodology

In Lean methodology, the primary focus is on maximizing value for the customer while minimizing waste. To achieve this, processes are typically categorized into three main types: Value-Added (VA), Non-Value Added (NVA), and Essential Non-Value Added (ENVA). Understanding these categories is crucial for optimizing operations and improving overall efficiency. This blog will explore each type, provide examples, and explain how they fit into the Lean framework.

What is Value-Added (VA)?

Value-Added activities are those that directly contribute to meeting customer needs. These are the processes that customers are willing to pay for because they add value to the final product or service. In Lean, the goal is to maximize these activities while minimizing or eliminating others that don't add value.

Examples of VA Processes:

Assembly of a product: In manufacturing, the actual assembly of parts to create the final product is a value-added activity because it directly contributes to the finished item that the customer buys.

Customer service interactions: Assisting customers in a way that enhances their experience with the product or service adds value from the customer's perspective.

What is Non-Value Added (NVA)?

Non-Value Added activities are those that consume resources but do not add any value from the customer's perspective. These activities are often seen as waste in Lean and should be eliminated or reduced as much as possible.

Examples of NVA Processes:

Waiting time: Time spent waiting for materials, approvals, or information is non-value added as it does not contribute to the final product and adds unnecessary delays.

Excessive transportation: Moving products or materials more than necessary within a facility is non-value added as it does not enhance the product and increases costs.

What is Essential Non-Value Added (ENVA)?

Essential Non-Value Added activities are processes that do not add direct value to the product or service but are necessary due to regulatory, safety, or operational requirements. While these activities do not enhance customer value, they cannot be entirely eliminated due to their importance in maintaining compliance or ensuring smooth operations.

Examples of ENVA Processes:

Regulatory compliance checks: Certain inspections or documentation processes are required by law or industry standards, even though they do not directly add value to the product.

Quality control procedures: While customers may not see the immediate value in these activities, they are essential for ensuring that the final product meets the required standards.

How to Manage VA, NVA, and ENVA in Lean

Identify and Categorize

Start by mapping out all processes within your operation. Categorize each activity as VA, NVA, or ENVA. This helps in visualizing where improvements can be made.

Focus on VA

Maximize value-added activities by streamlining processes and eliminating any obstacles that hinder efficiency. Focus on what directly contributes to customer satisfaction.

Eliminate or Reduce NVA

Identify non-value-added activities and work on eliminating them where possible. If they cannot be eliminated, find ways to reduce their impact on the overall process.

Optimize ENVA

While essential non-value-added activities cannot be removed, they can be optimized. Look for ways to make these processes more efficient, such as automating compliance checks or streamlining documentation procedures.

Real-World Application of VA, NVA, and ENVA

Case Study: Lean Implementation in Healthcare In a hospital setting, patient care activities such as diagnostics, treatment, and consultation are value-added processes.

Activities like filling out extensive paperwork or waiting for test results are non-value-added and should be minimized. However, certain ENVA activities, such as sterilization procedures or compliance with medical regulations, are essential but do not directly add value from the patient's perspective. By identifying and optimizing these activities, the hospital can improve patient care quality while reducing operational costs.

Conclusion

Understanding and managing Value-Added (VA), Non-Value Added (NVA), and Essential Non-Value Added (ENVA) processes is fundamental to the success of Lean methodology. By focusing on maximizing value-added activities and minimizing waste, businesses can enhance efficiency, reduce costs, and deliver higher quality products or services to their customers.

Whether in manufacturing, healthcare, or any other industry, applying these principles can lead to significant improvements in operational performance.

Comments